Pipeline prefabrication

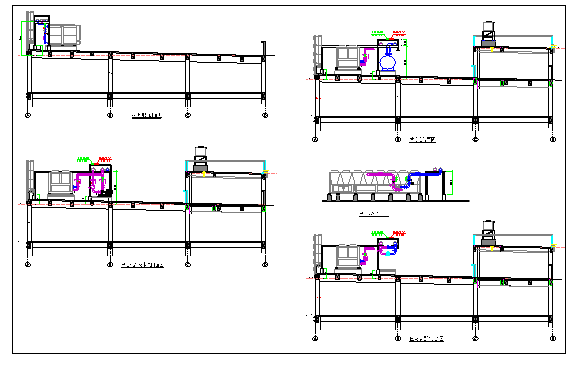

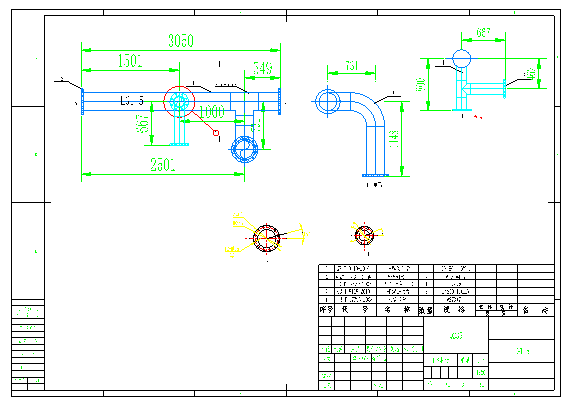

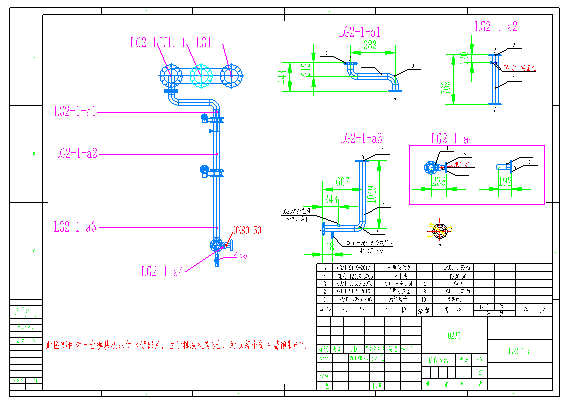

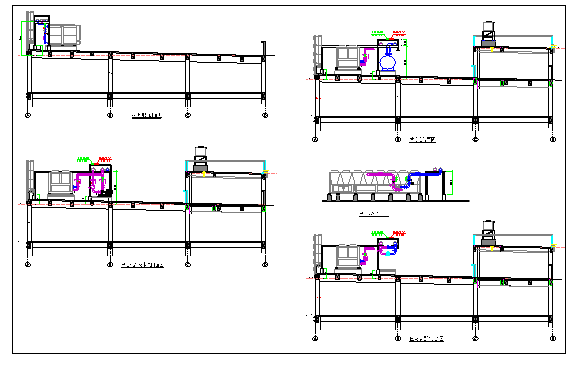

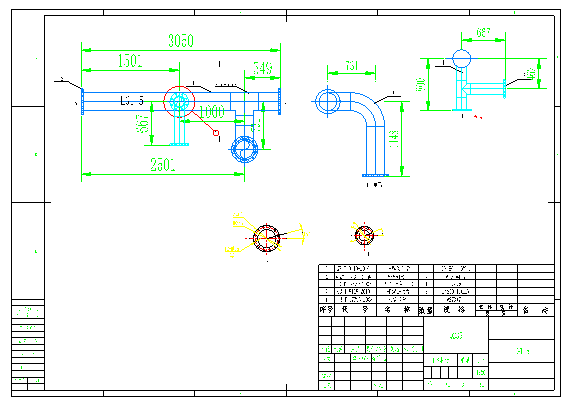

1. First, according to the construction drawings and site requirements of the Design Institute, rearrange the pipeline and make a prefabricated plane sketch, as shown in the following figure.

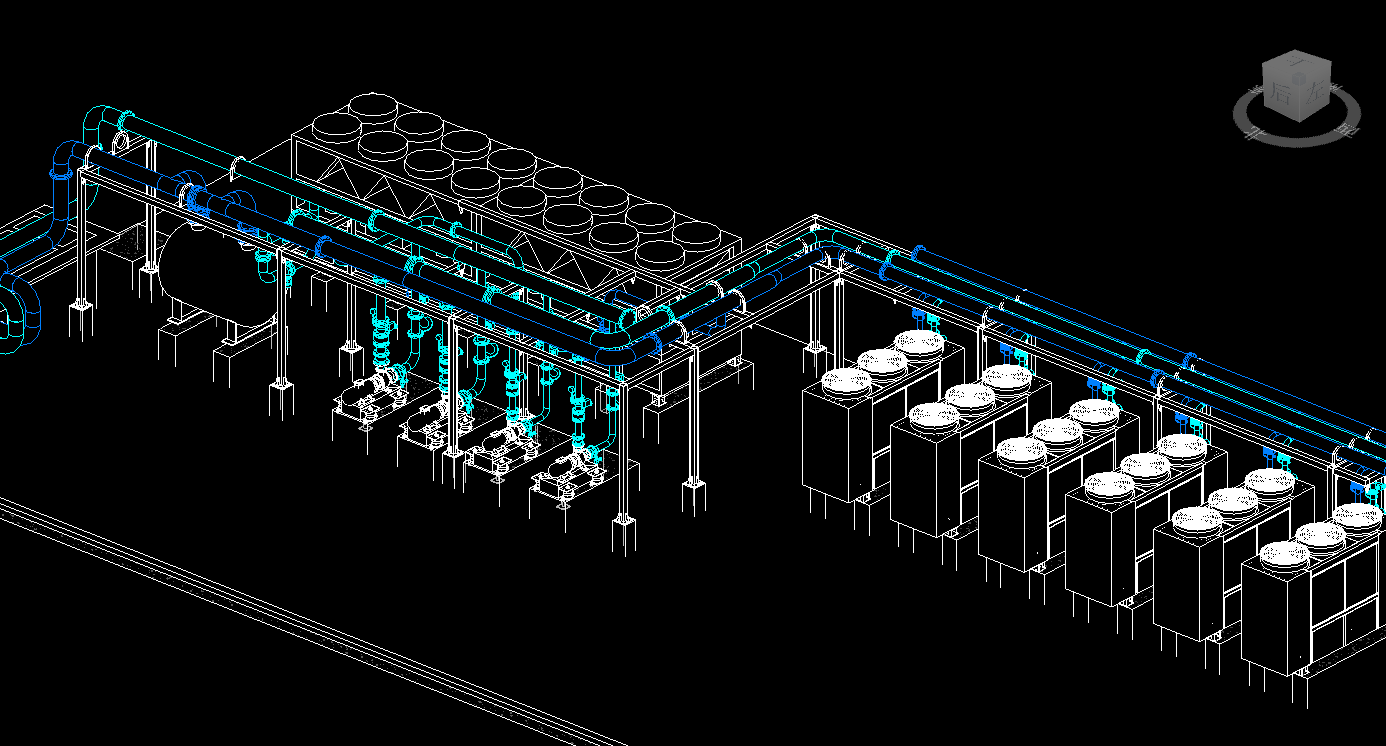

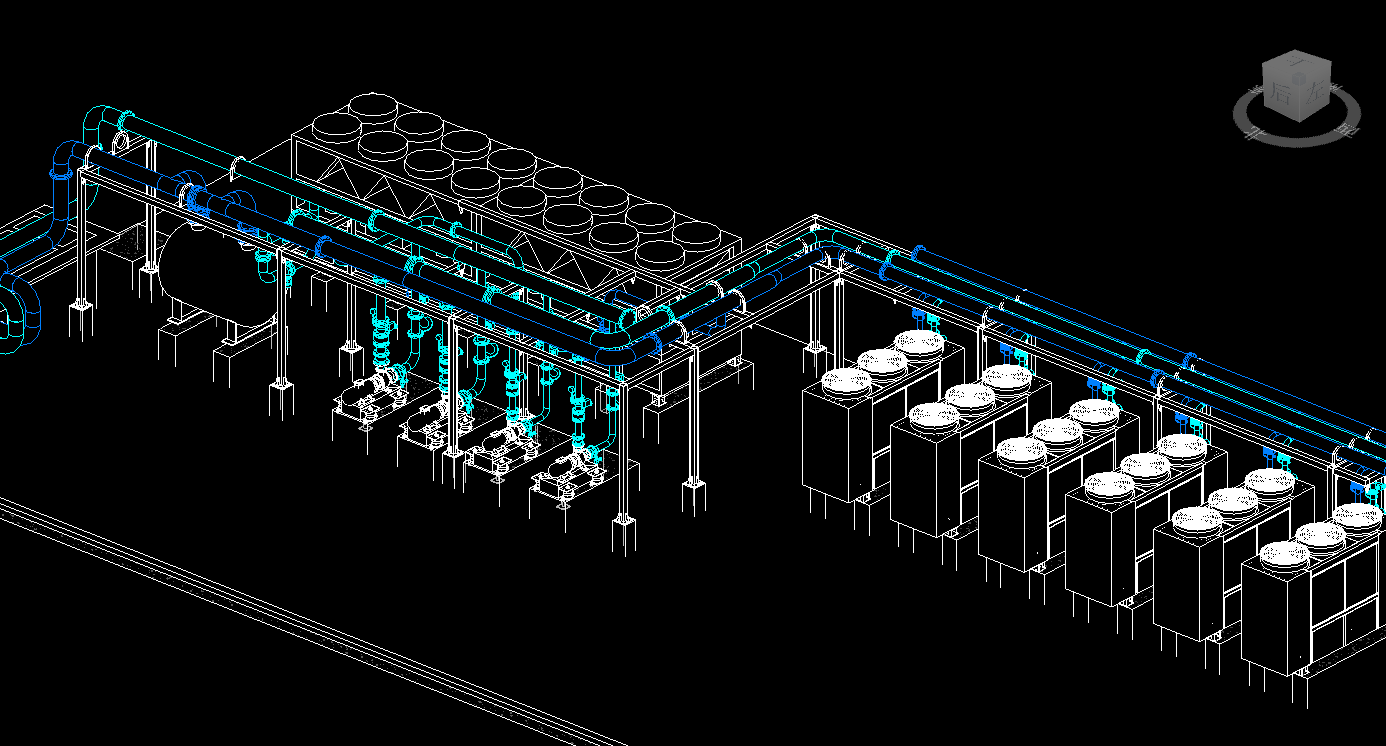

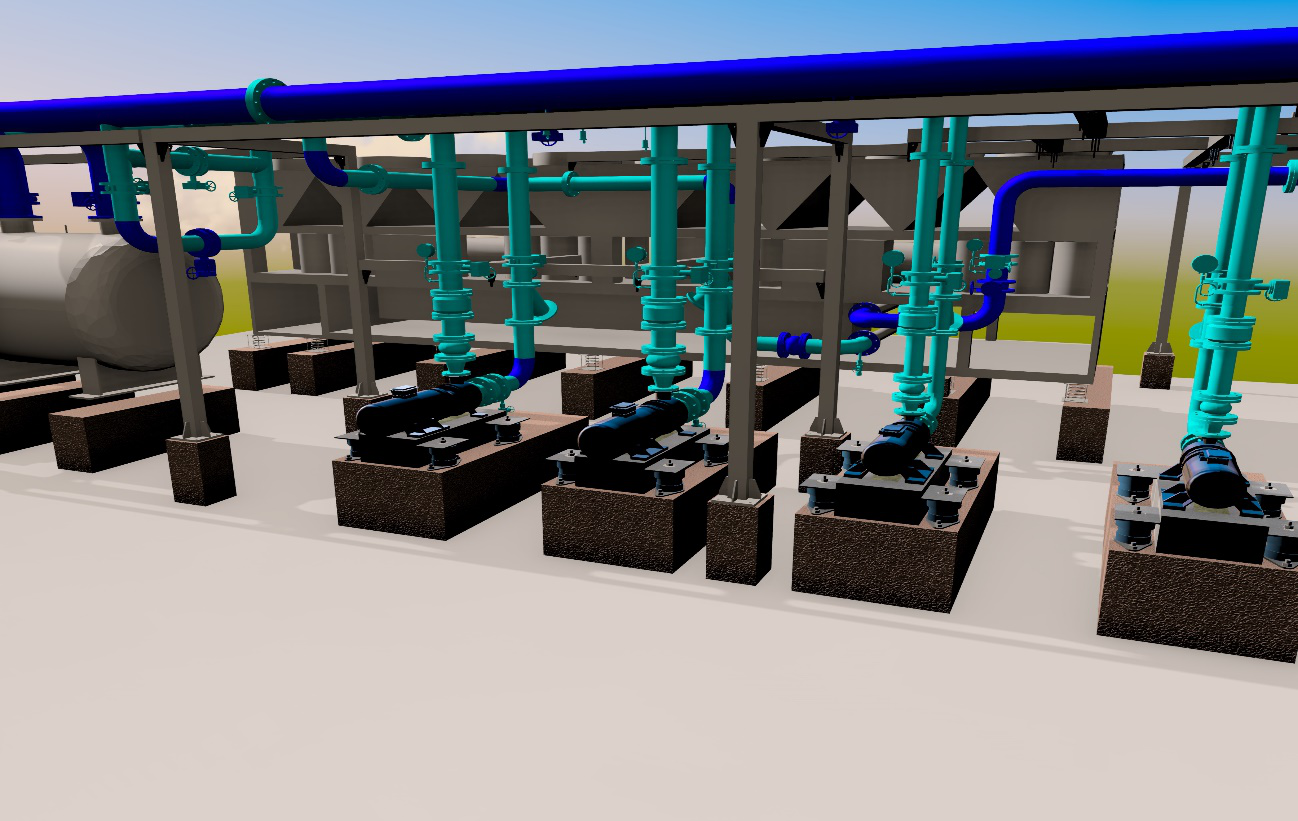

2. According to the determined scheme and sketch, make the three-dimensional BIM model (generally using Revit software), determine the elevation, check the collision, and form the final BIM drawing.

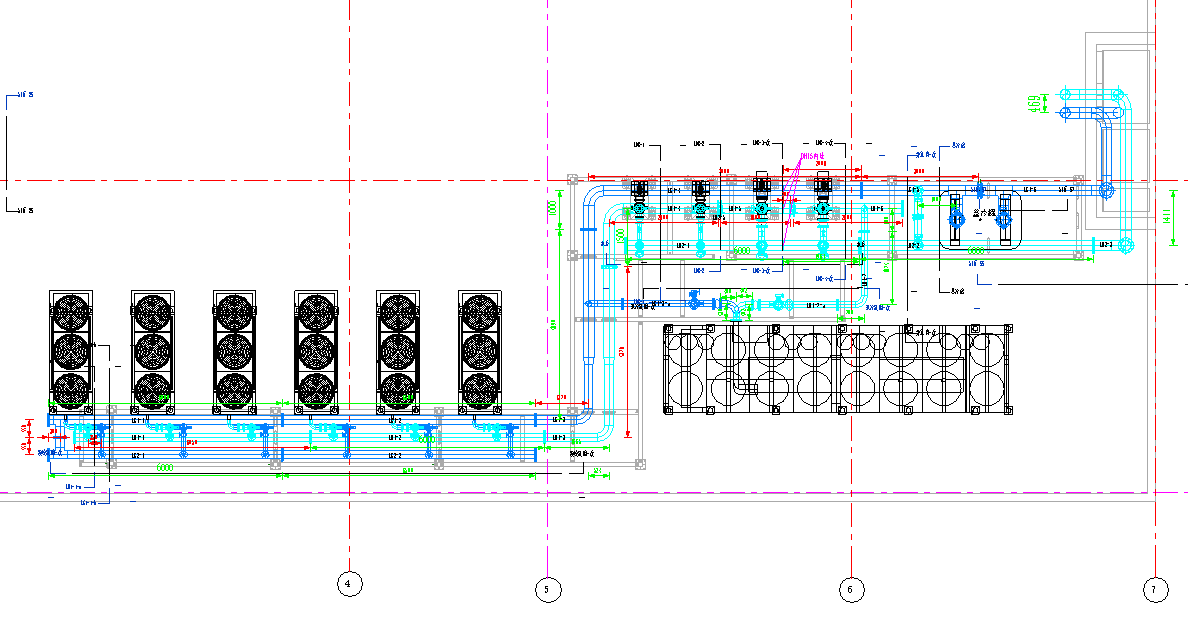

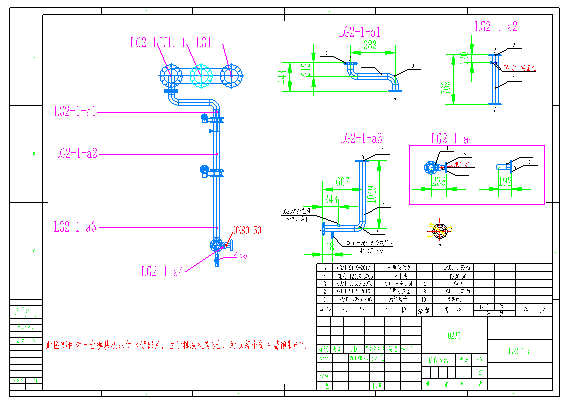

3. Discuss and demonstrate the three-dimensional drawing, determine the elevation and direction again, and after confirmation, carry out dimension marking and pipe section number, and export the processing drawing.

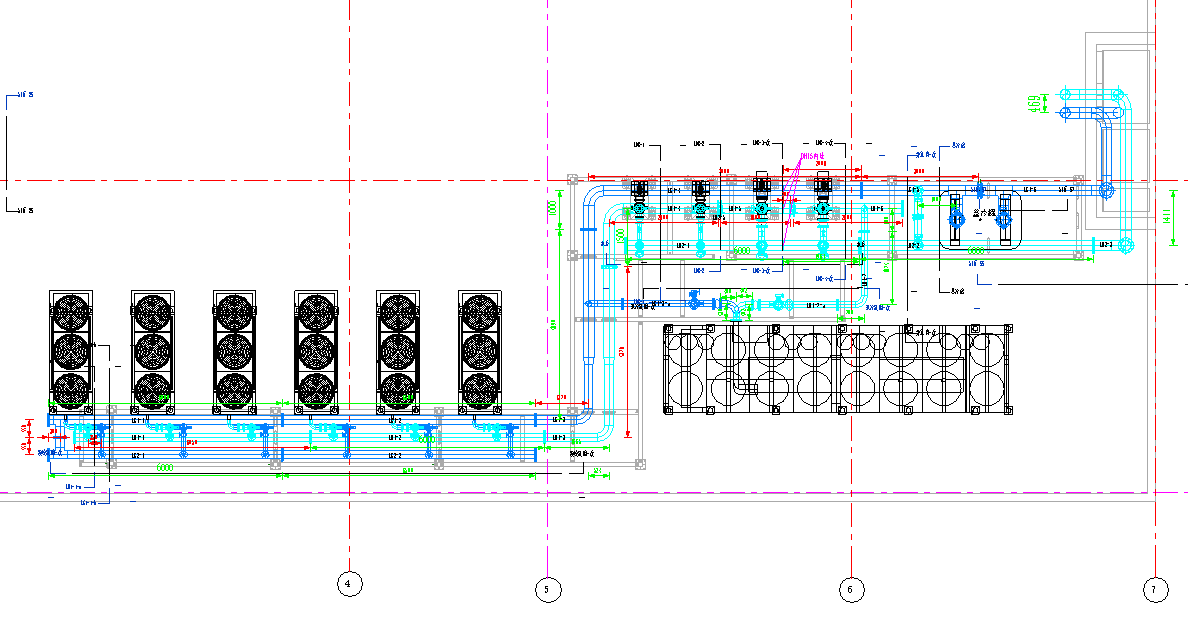

4. The example of the exported prefabrication drawing is as follows.

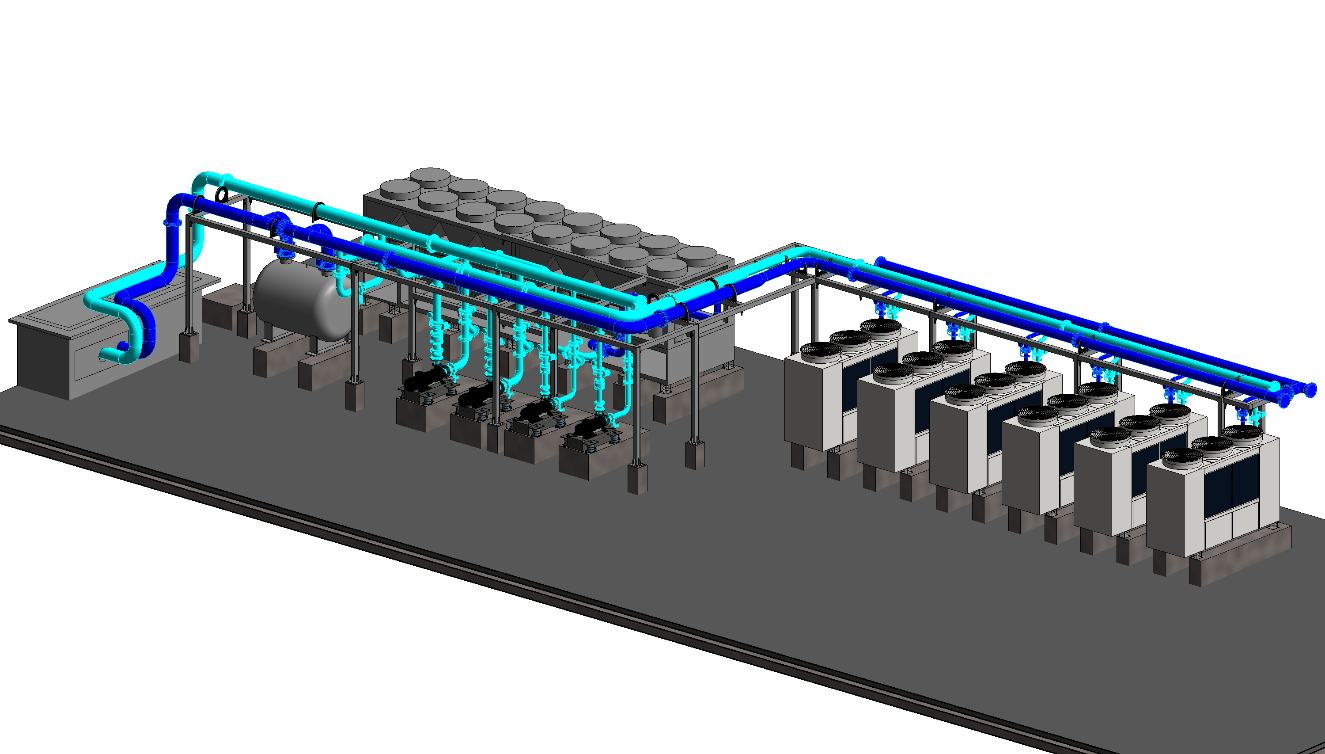

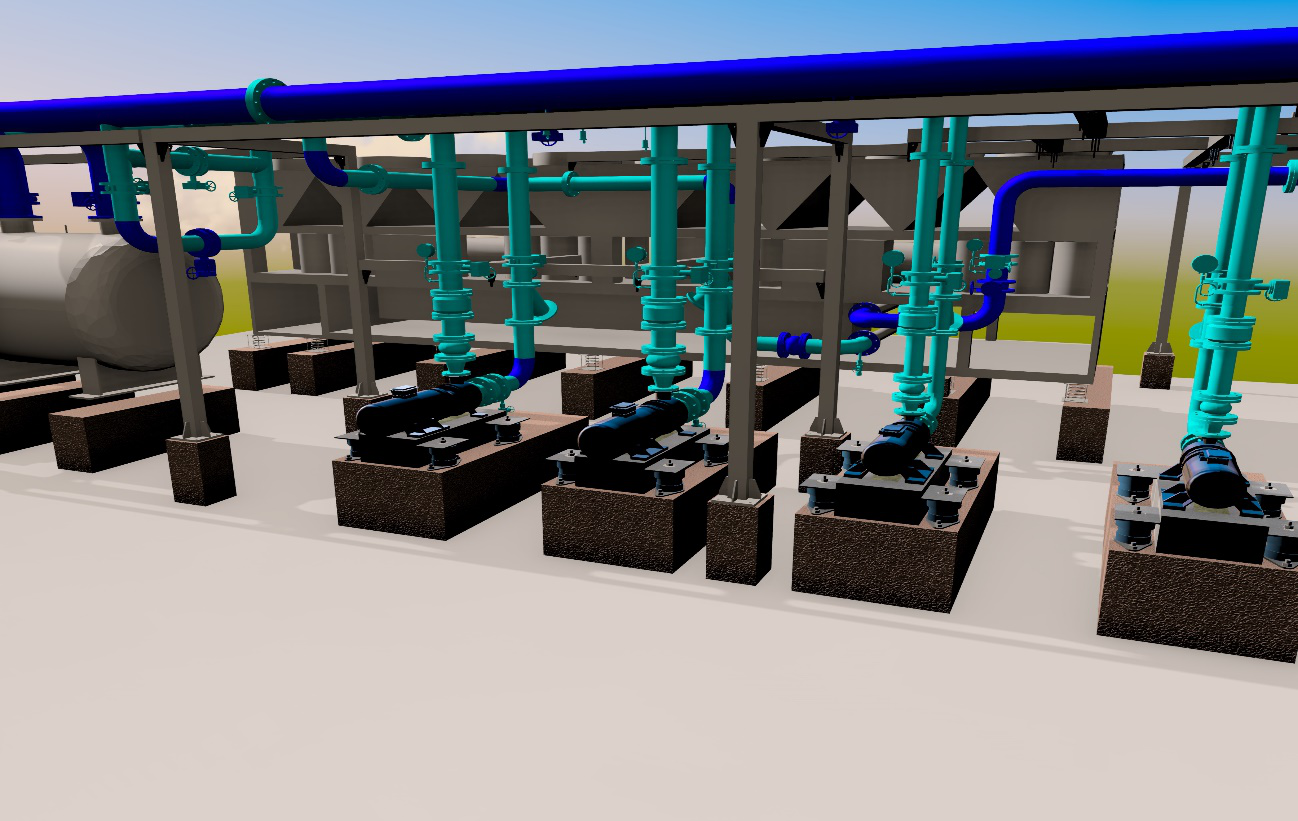

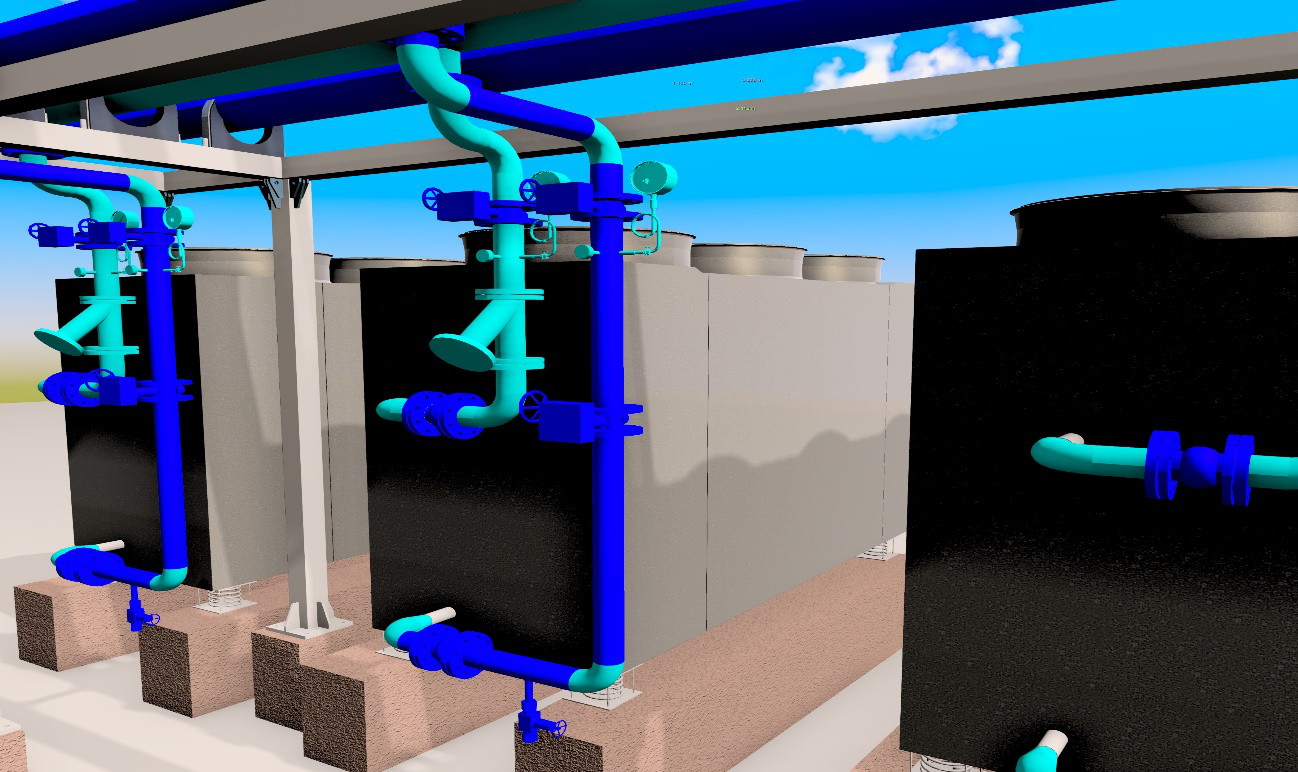

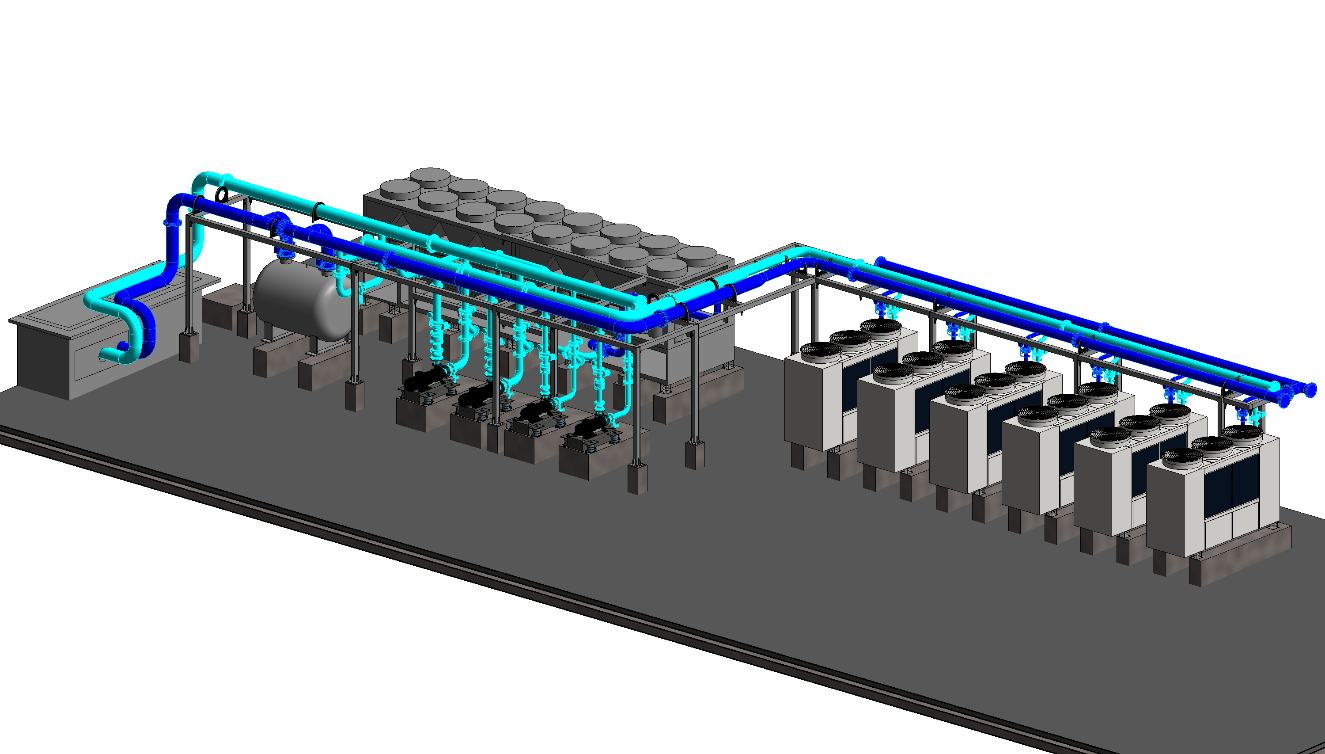

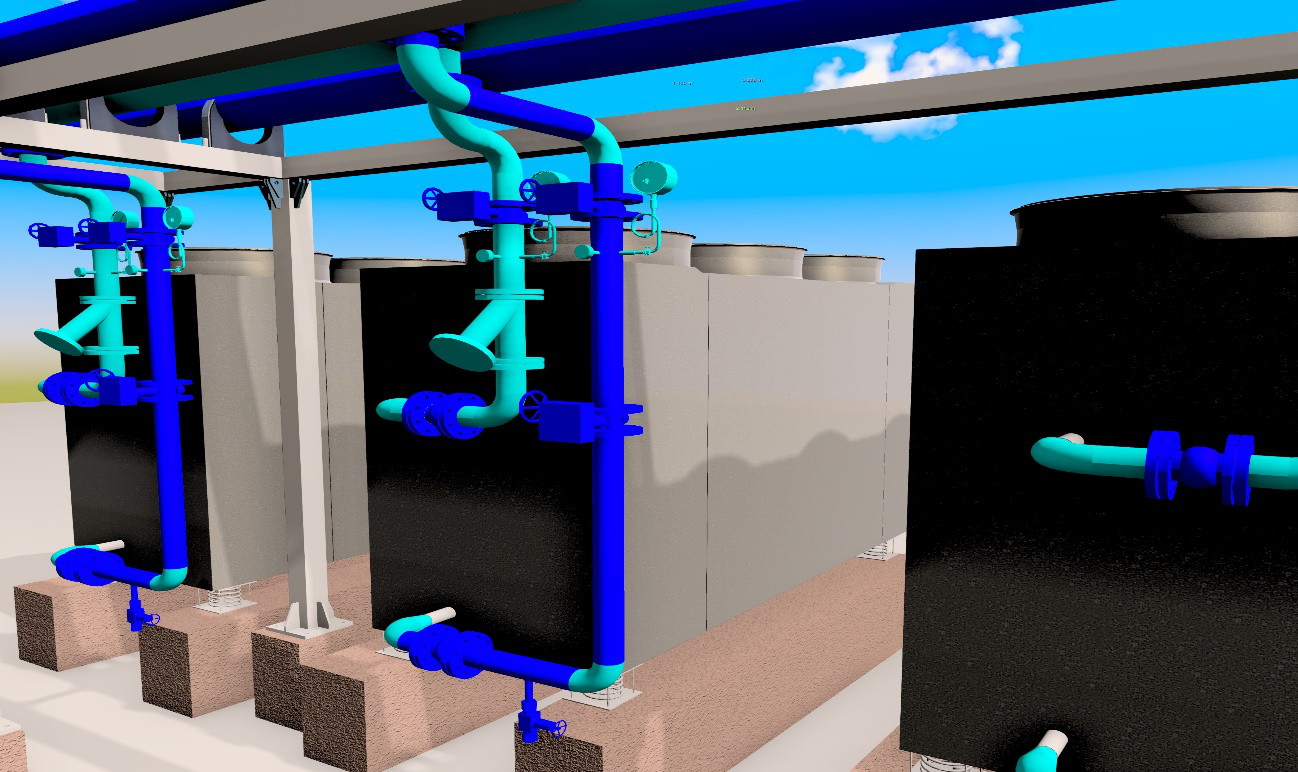

5. After the processing drawing is completed, the representative three-dimensional drawing will be rendered, so as to explain the disclosure to the workers and facilitate the workers to understand the specific practices, as shown below.

6. According to the confirmed processing drawings, the pipeline prefabrication shall be carried out in the processing yard. During the processing, the precision and flange screw hole angle shall be strictly controlled, and the pre assembly shall be carried out.

7. After the prefabrication of all pipelines is completed, they shall be transported to the construction site according to the plan for formal butt assembly.

8. Legend of formal butt assembly.

中文

中文 English

English